Project

This project documents the design and assembly of a mechanical clock.

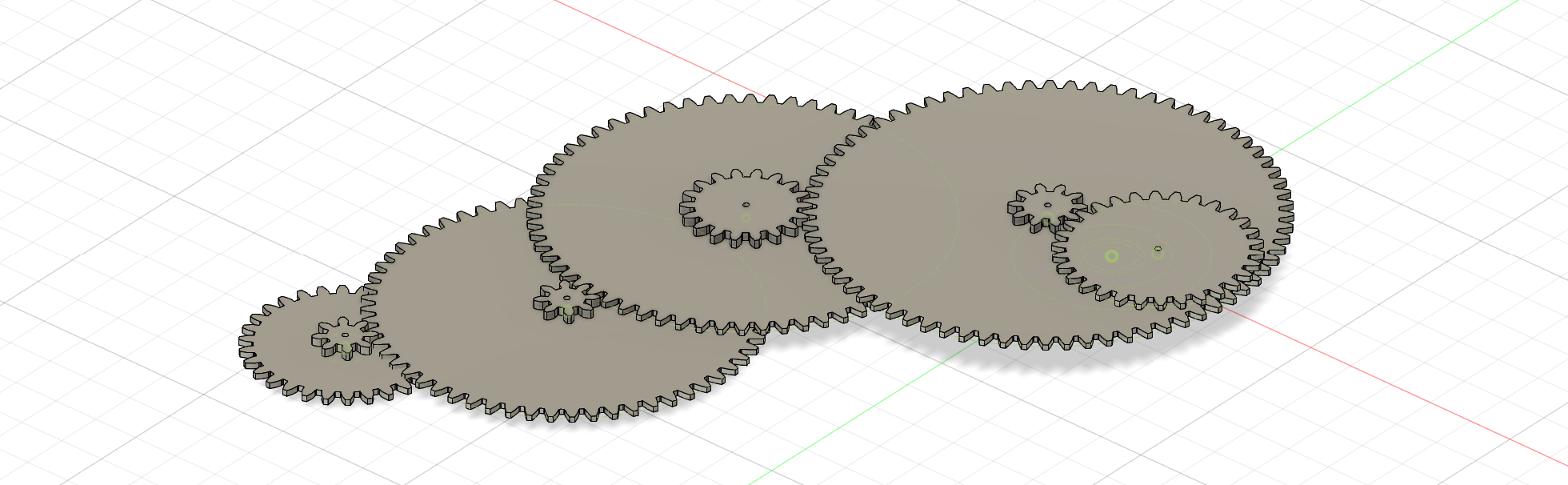

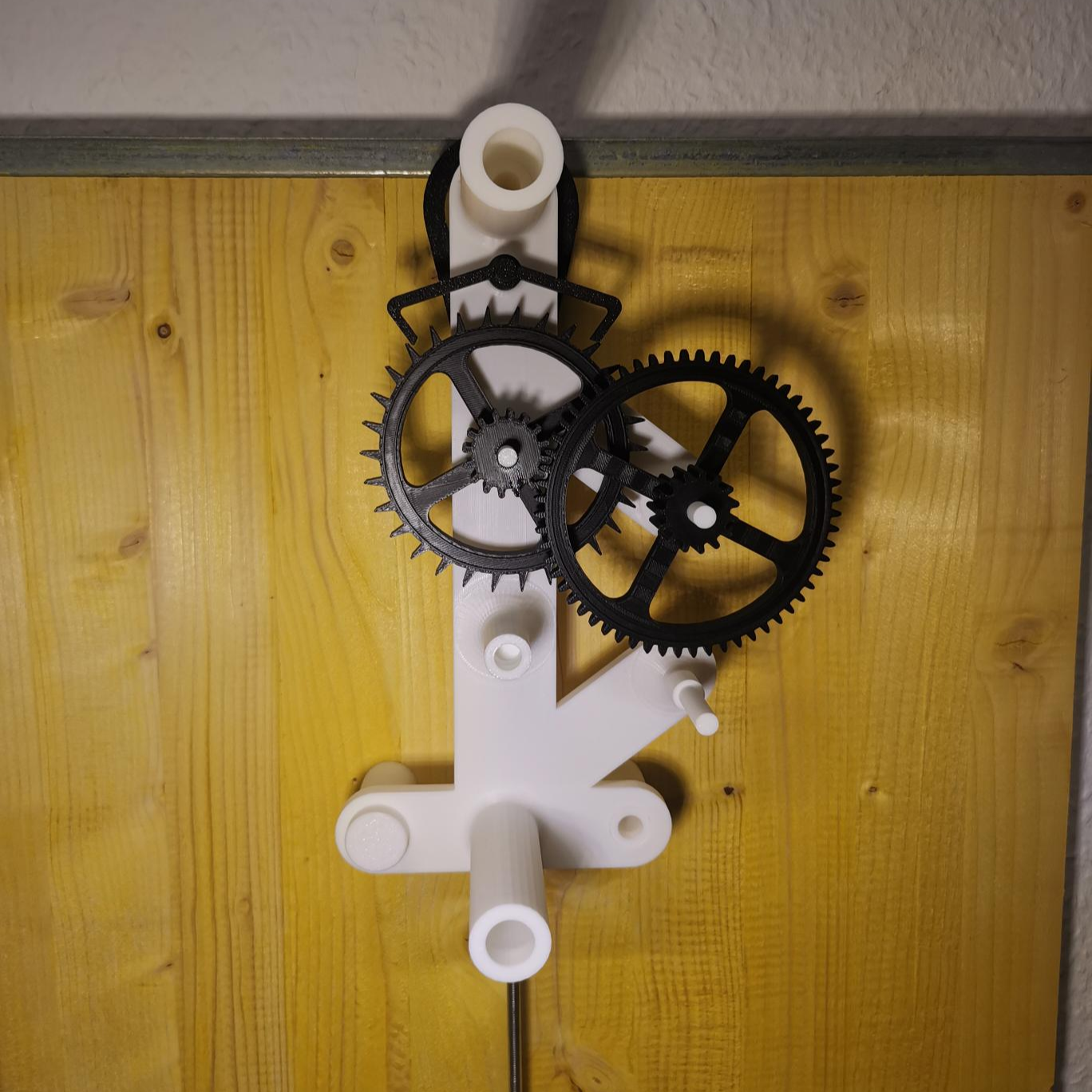

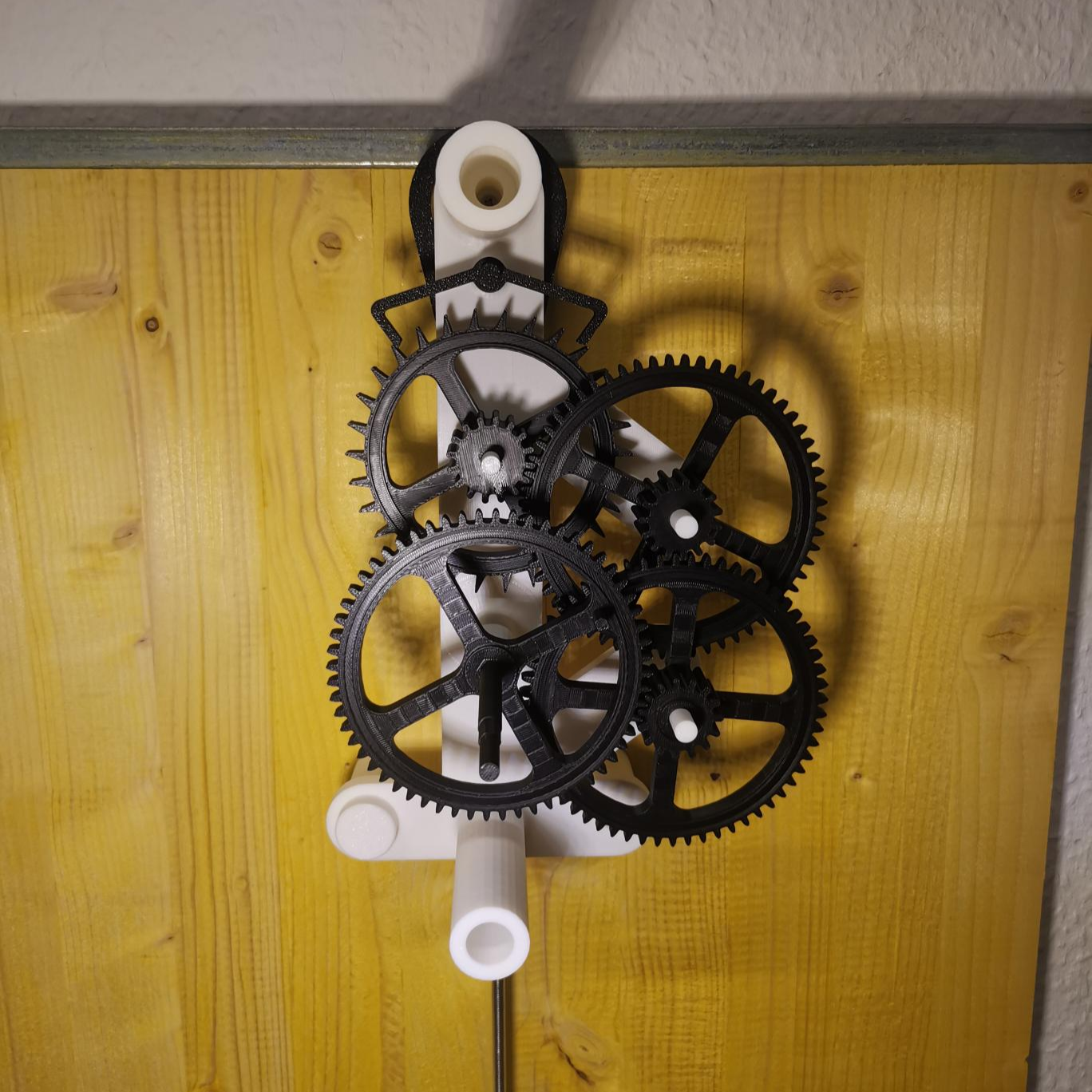

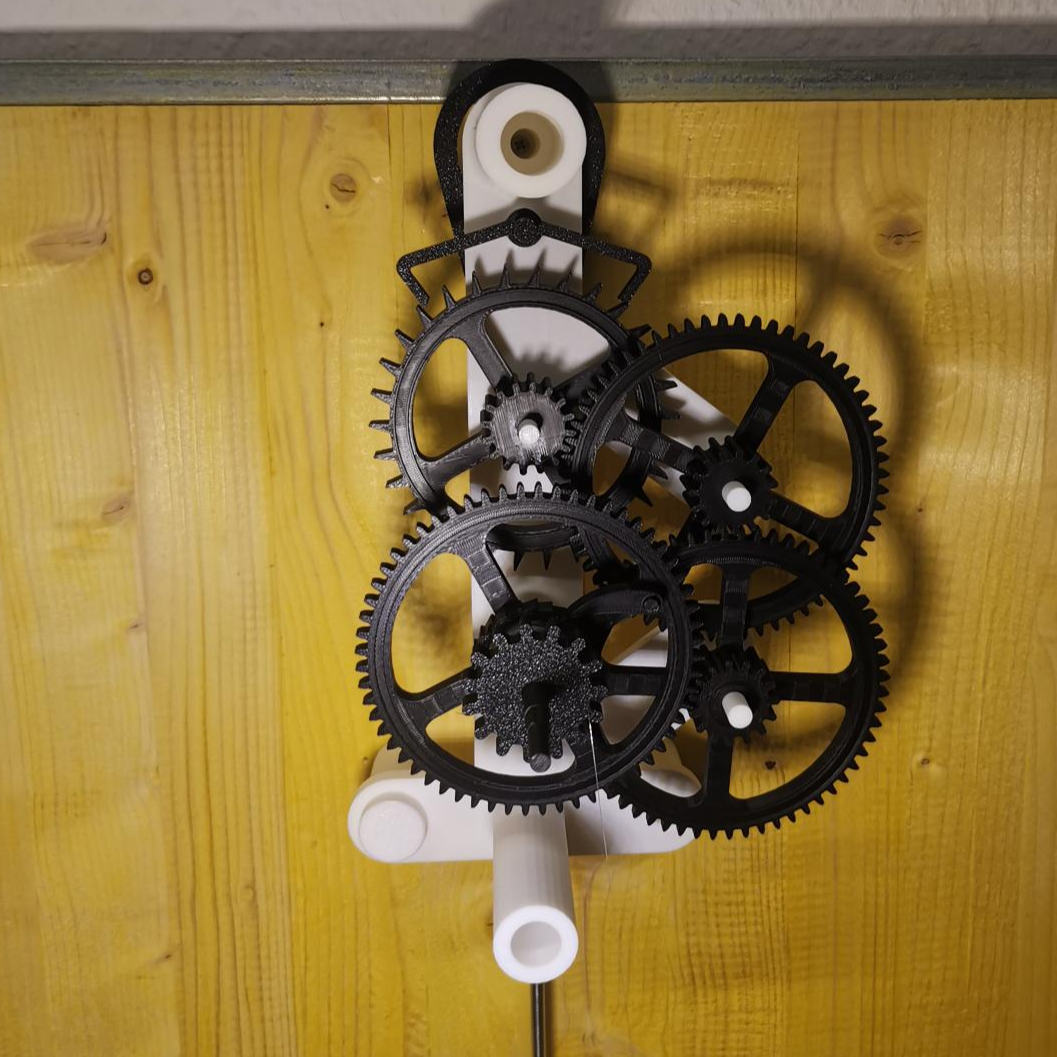

Gear train

I Designed a simple gear train to look at the basic principle how an easy mechanical clock works.

| Gear Position | Wheel Teeth | Pinion Teeth |

|---|---|---|

| Escapement | 30 | 8 |

| Intermediate | 60 | 8 |

| Minute | 64 | 18 |

| Intermediate | 72 | 10 |

| Hour | 30 | |

If the escapement gear turns once a minute, a ratio of 60:1 is needed for the minute gear to turn once per hour.

Total ratio escapement to minute wheel: (60/8) × (64/8) = 7.5 × 8 = 60:1

For the hour gear to turn once per hour, a 12:1 ratio is needed from the minute to the hour gear.

Total ratio minute to hour wheel: (72/18) × (30/10) = 4 × 3 = 12:1

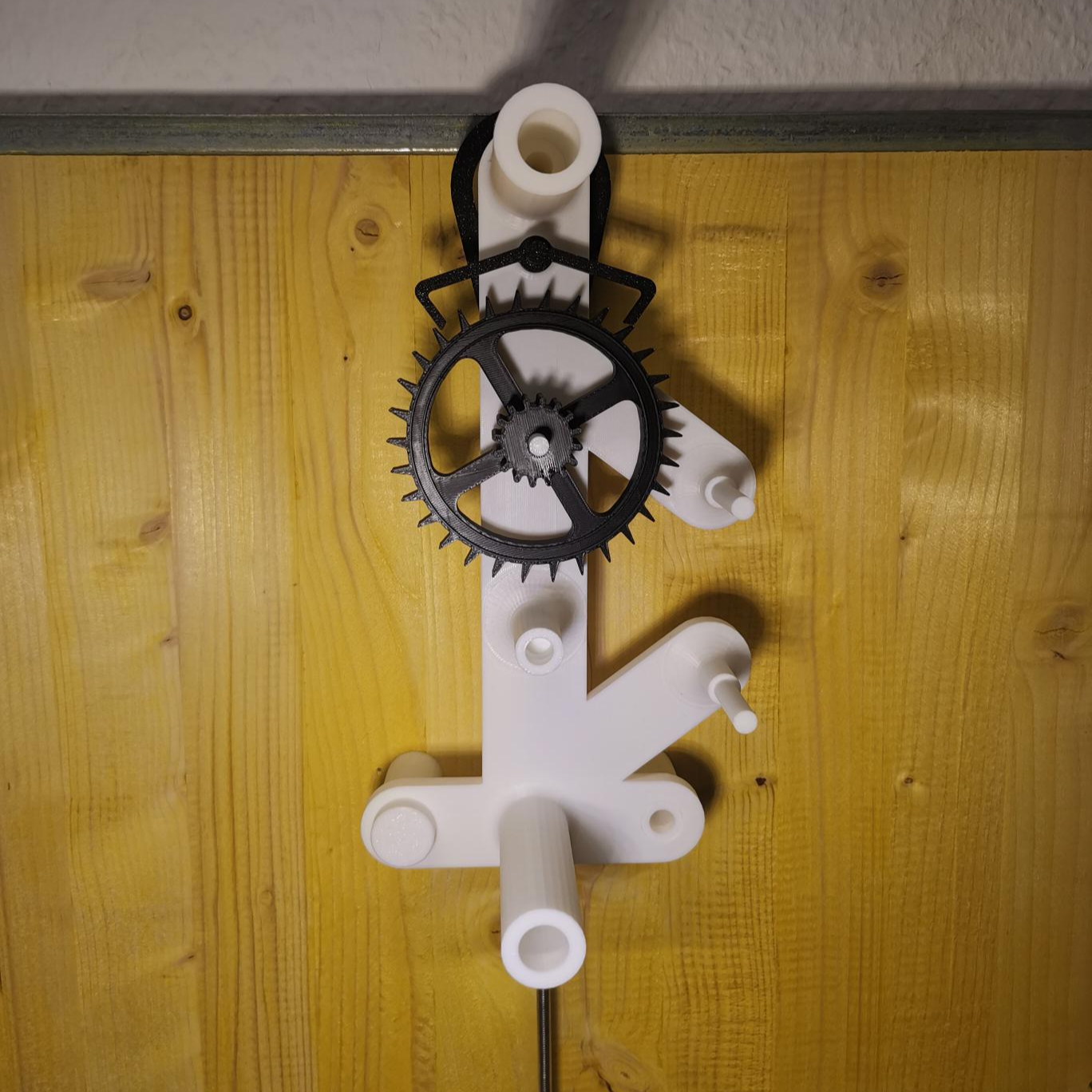

Escapement

To try escapement mechanisms a swiss lever escapement was 3D printed. The model was taken from Makerworld.

The initial 3D print of the Swiss lever escapement on the Prusa MK4 failed to function reliably. It initially ticked 2-5 times before stopping, and later the drive weight fell continuously as the pallet fork failed to lock the escape wheel.

Probable causes:

- Low print quality: surface resolution and accuracy on Prusa MK4 ->surfaces too rough, preventing smooth unlocking/locking

- Dimensional inaccuracies: Critical tolerances (0.1-0.2mm for lever drop, fork angles) exceeded due to print shrinkage or extrusion inconsistencies.

Switched to a pendulum escapement because the Swiss lever's ultra-precise tolerances (0.1mm) and smooth surfaces proved unreliable with Prusa MK4 3D printing quality, while pendulums offer more forgiving mechanics with larger clearances.

- Gravity-driven → Less friction-sensitive vs. spring tension

- Longer period (2s swing) → Easier to manufacture and debug

- Visual feedback during testing

Pendulum advantages:

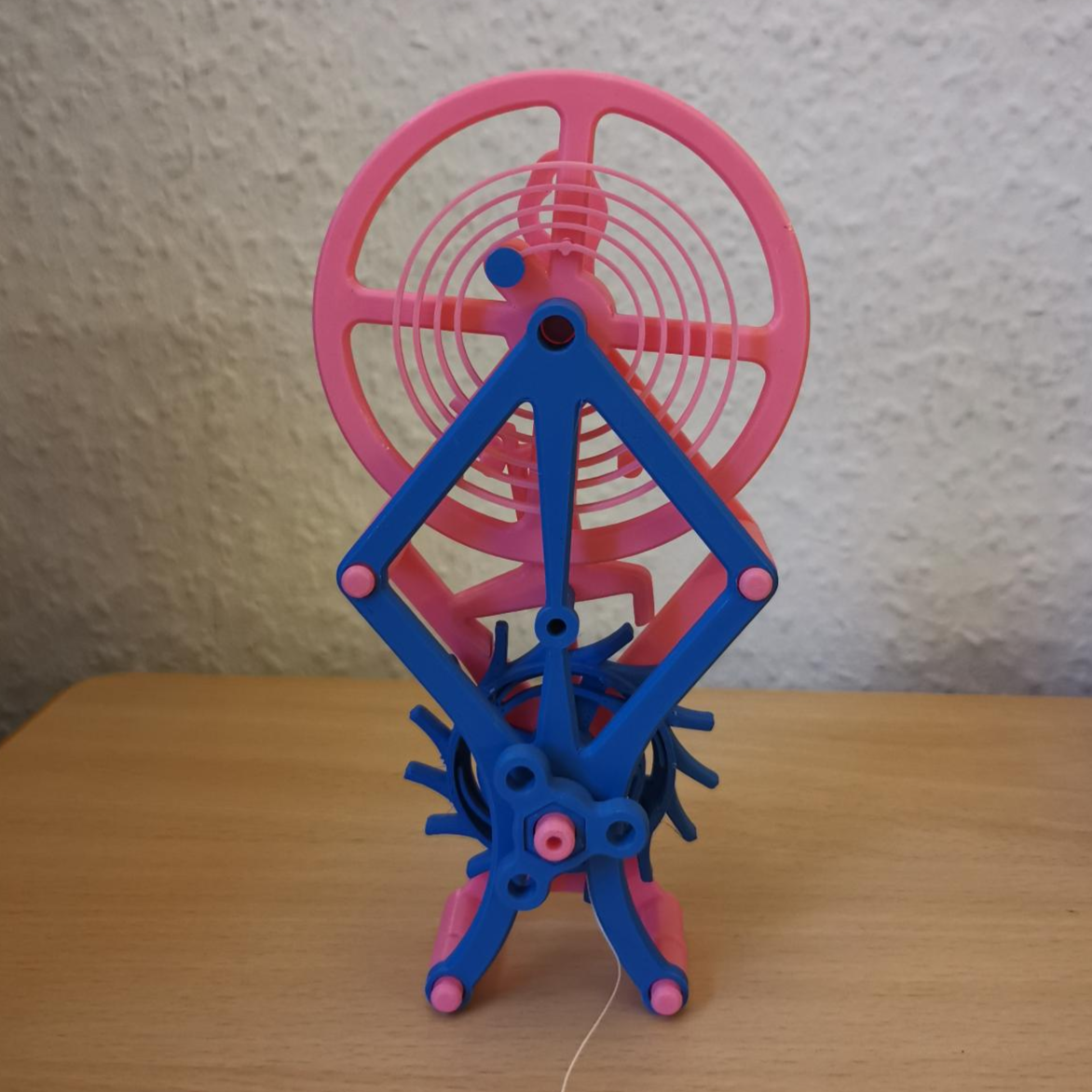

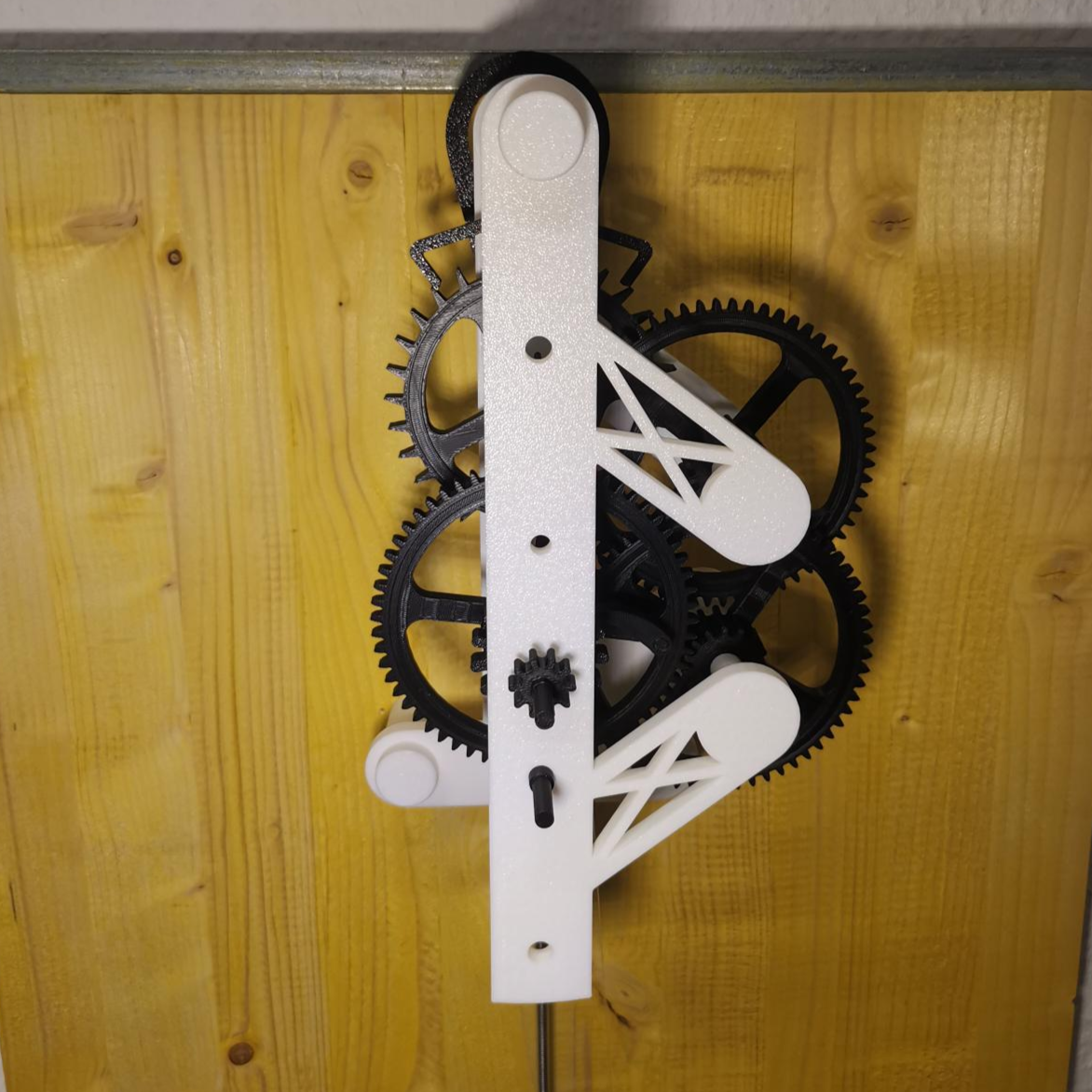

Pendulum Clock

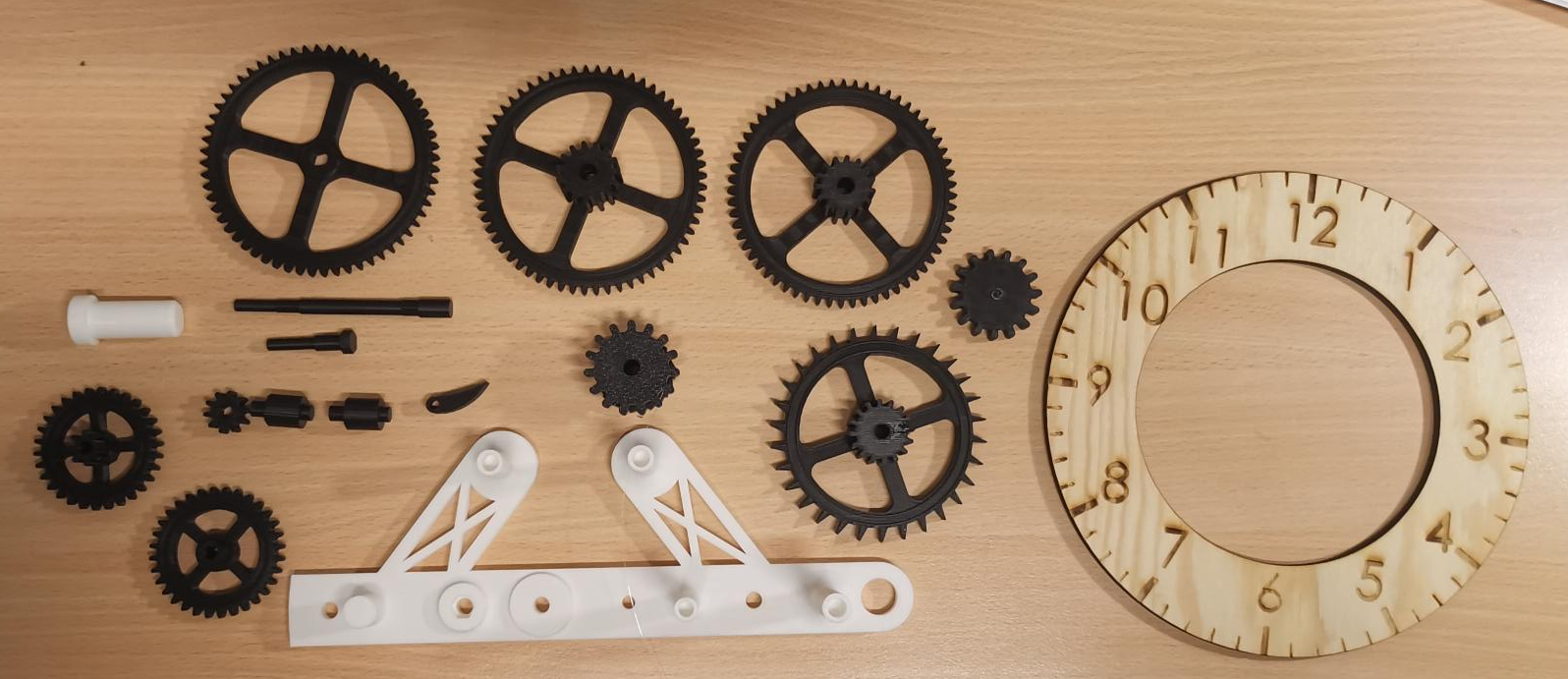

The 3D-model of the clock was taken from Makerworld

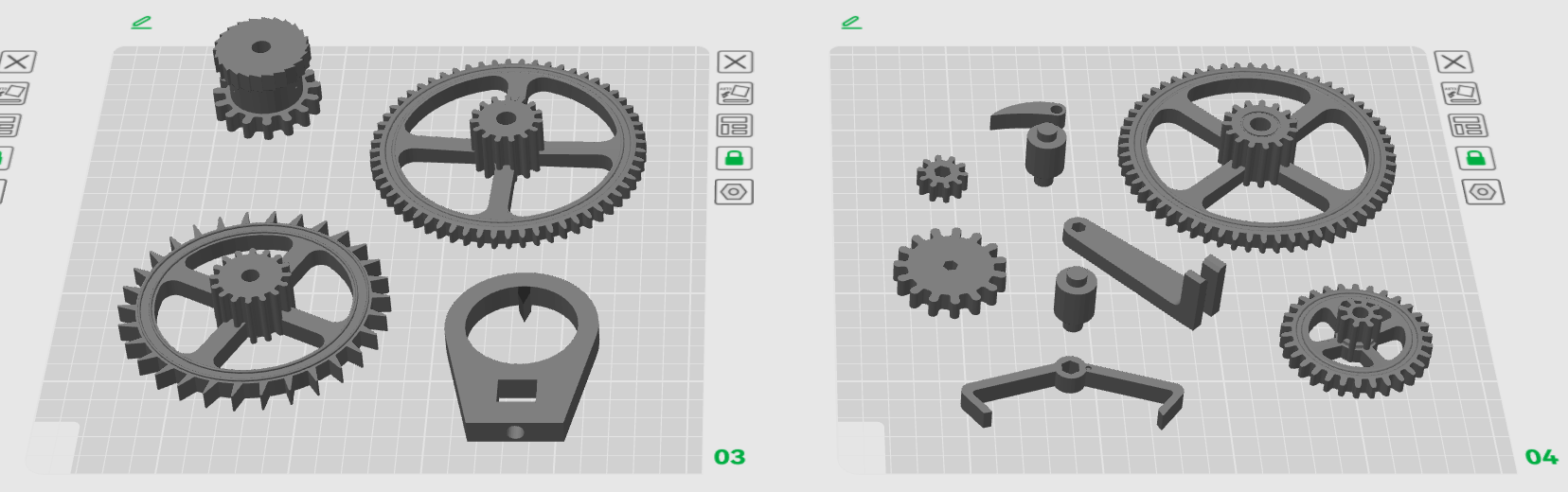

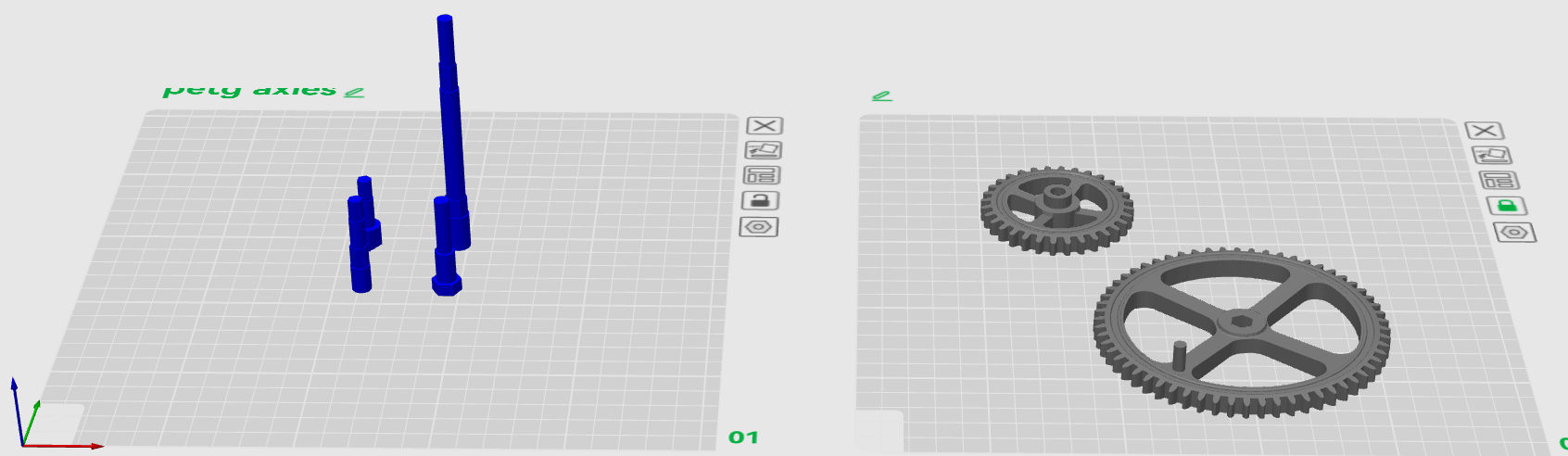

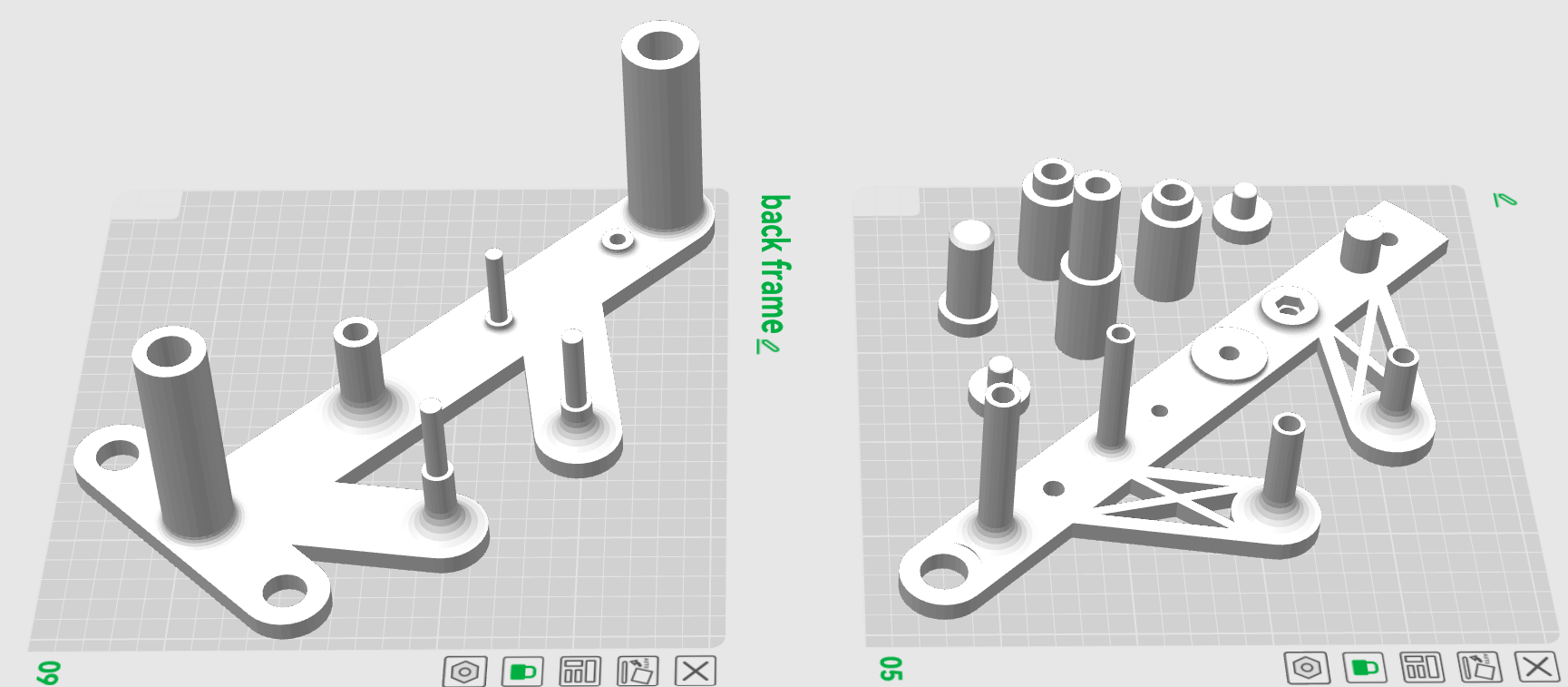

Printing of Parts

All parts were printed using a Bambulab P1S, 0.4mm nozzle and post-processed with a lighter and knife for deburring.

Additional non 3D-printed parts

- M6 threaded rod 1m

- M6 threaded rod 0.3m

- M6 nuts

- Rod coupler

- fishing line

- wood screws for mounting

- lubricant

Assembly

First testrun

The initial test ran for 30 minutes before stopping, likely due to the pendulum weight rotating and getting stuck on the wooden backplate.

Testet weight (beer 0,3) works

Second testrun

After fixing the pendulum weight, the second run operated smoothly with only a 1-minute offset after one full hour of runtime.

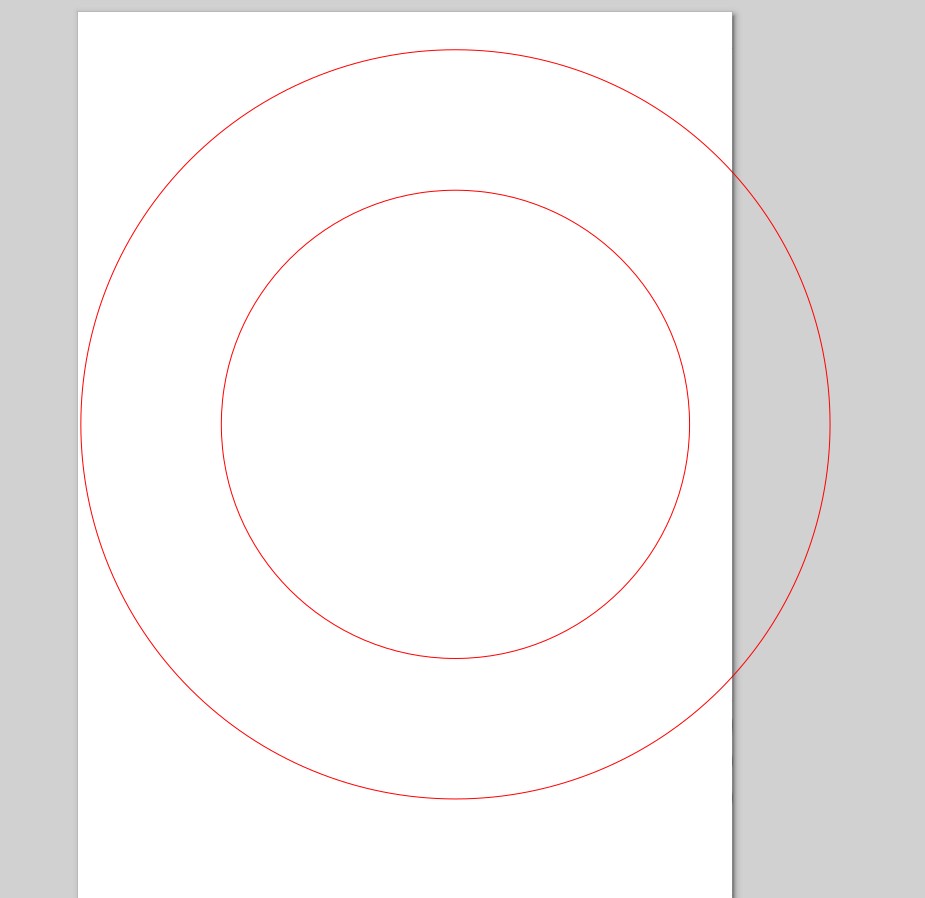

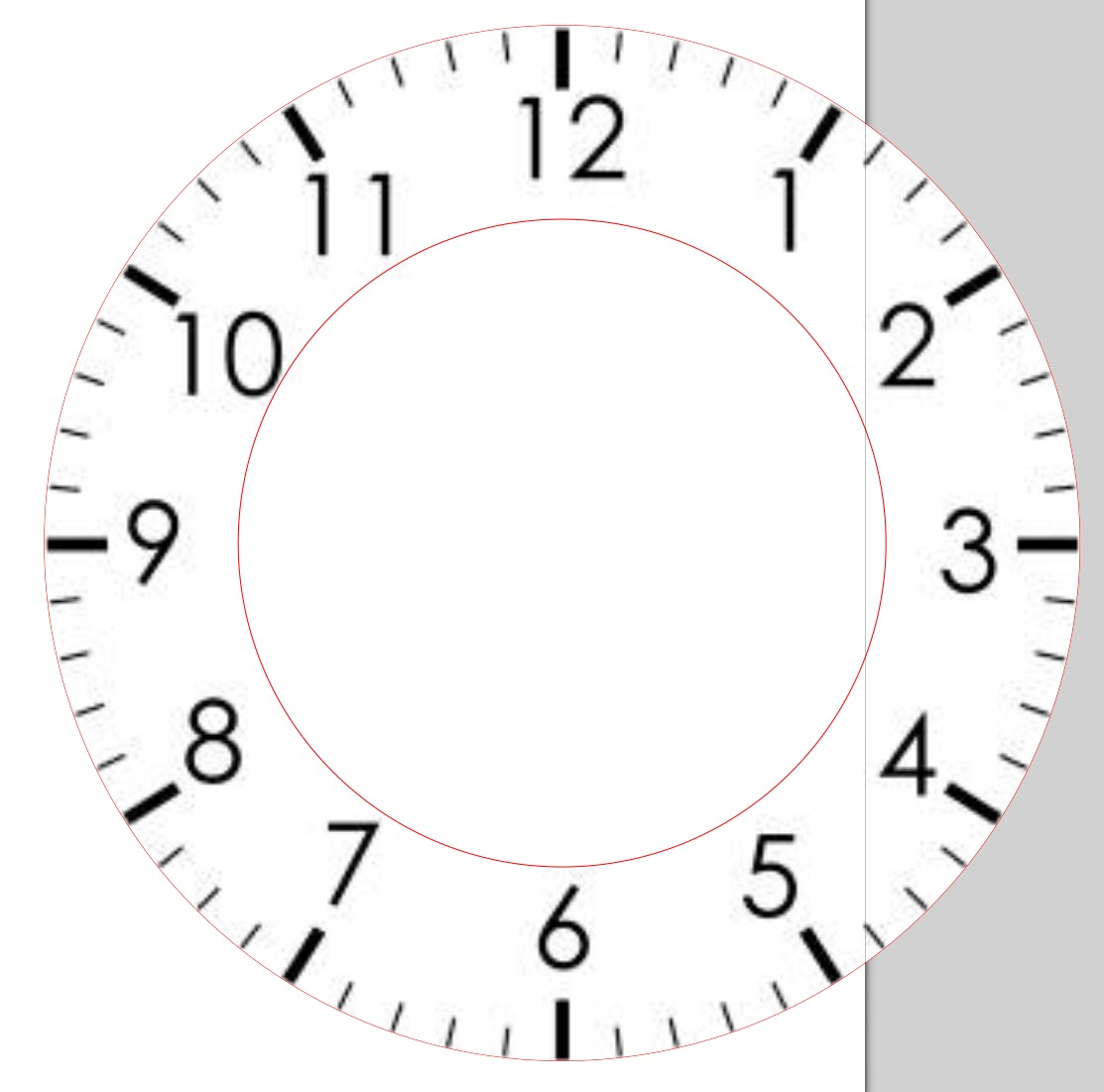

Watchface

To create a custom watchface, laser cutting/engraving was used.

- Incscape

- Setup circle 240mm (red Hairline to cut)

- Center circle 150mm (red Hairline to cut)

- Group

- Add picture of watch face

- Create Bitmap of picture

- Use grouped circles to cut watch face

- Export as .svg

- Cut/engrave with Lasercutter trotec speedy 100 C 40

- final pruduct

Problem

The weight that powers the clock will over time bend the main bolt nad lock the mechanism eventually.

Solution: different material(metal)

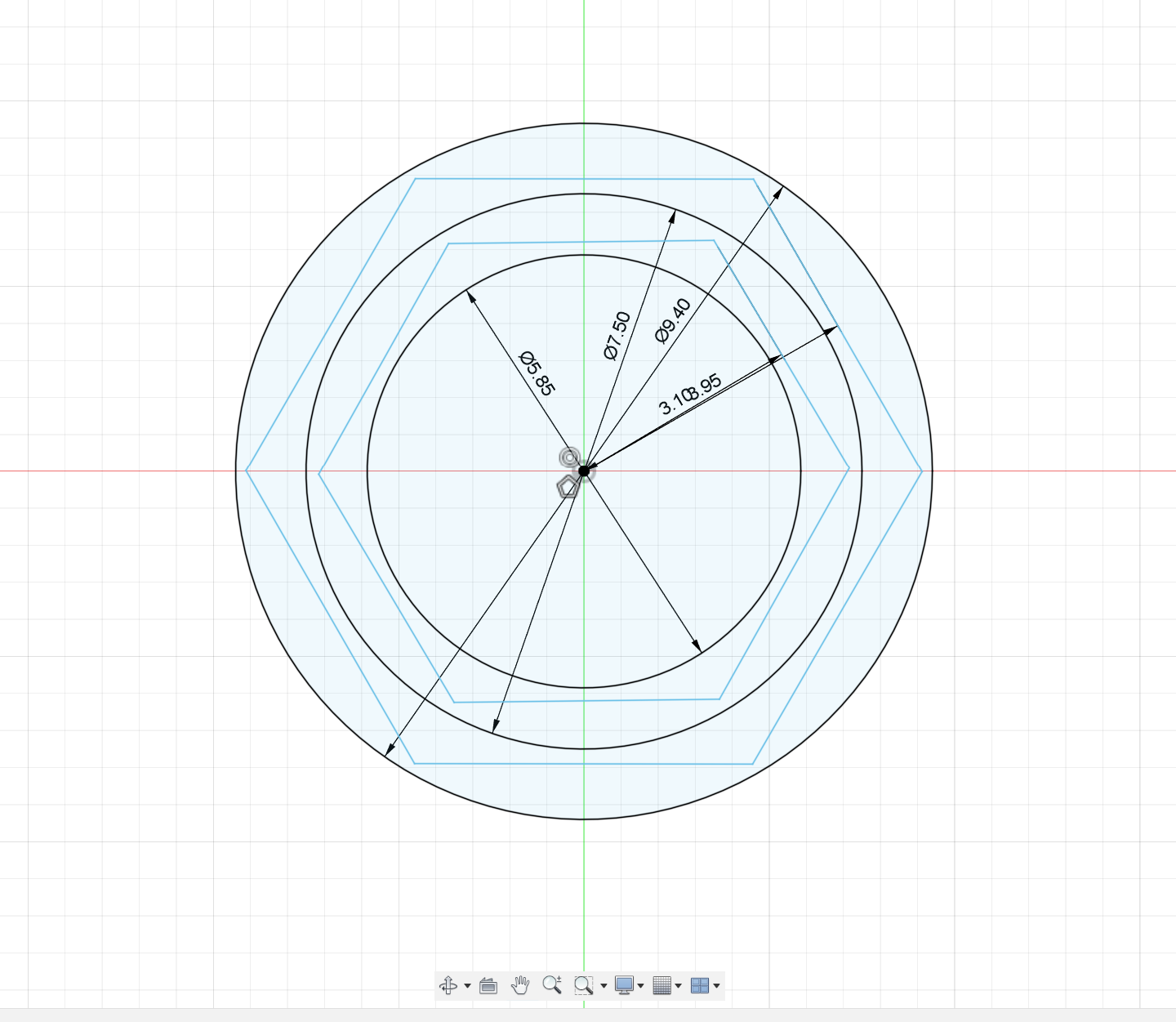

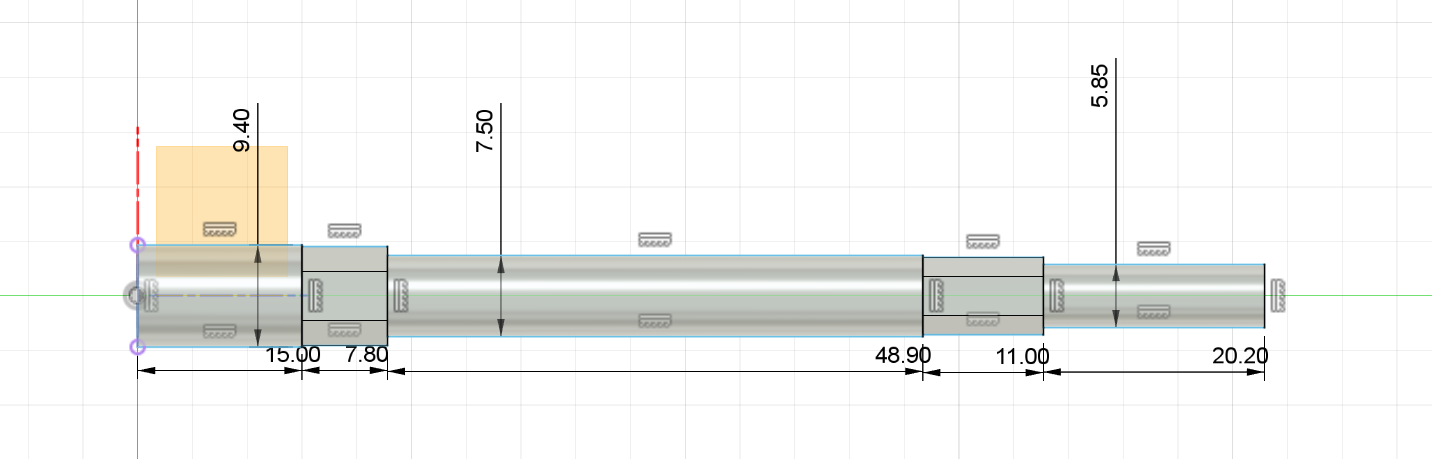

- ⌀5.85mm

- inner circle Hex ⌀6.2mm

- ⌀7.5mm

- inner circle Hex ⌀7.9mm

- ⌀9.4mm

Lathe

Starting with a turning blank brass ⌀10mm

Blank was bend -> not safe to workk with in lathe.

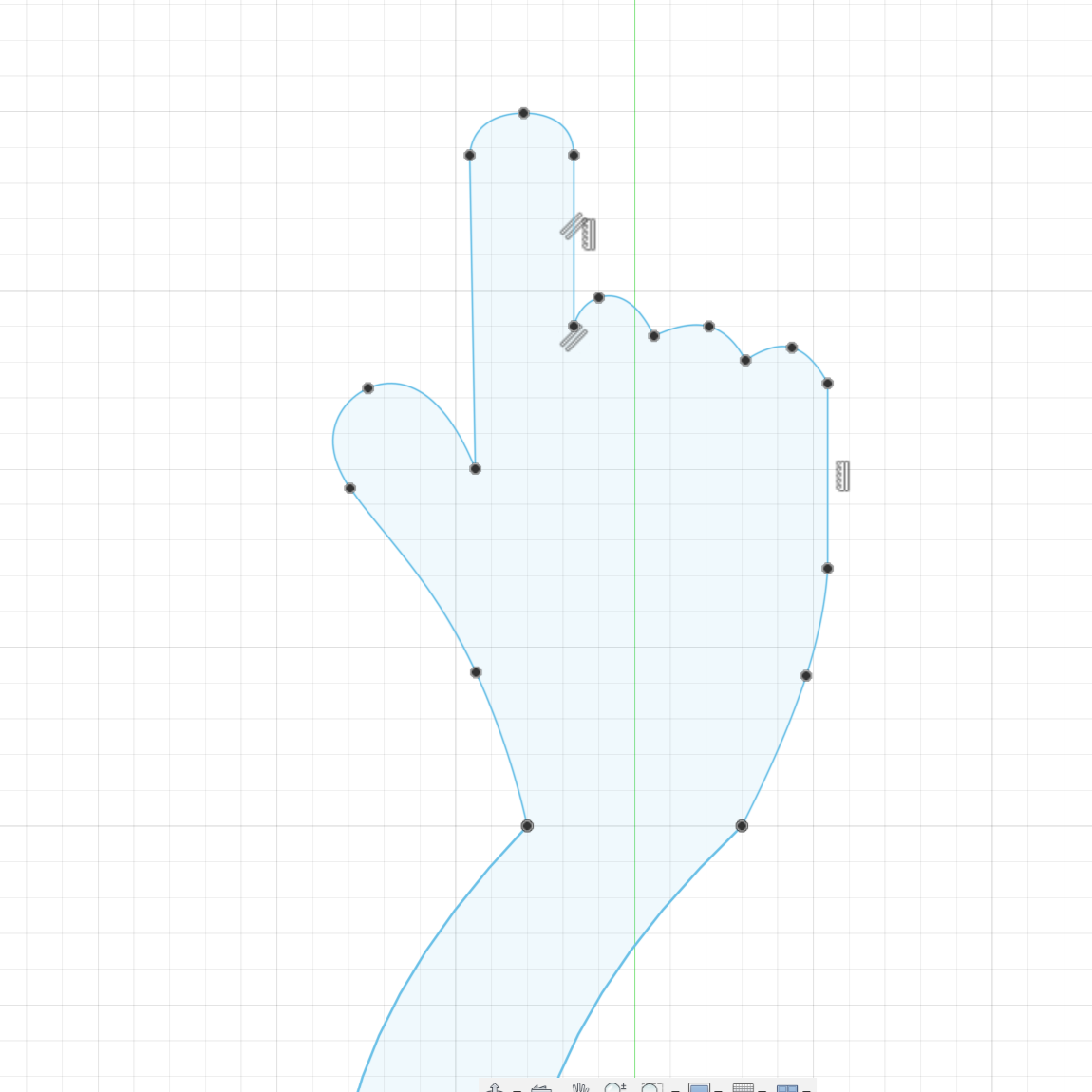

Watch Hands

⌀6mm

⌀11.5mm

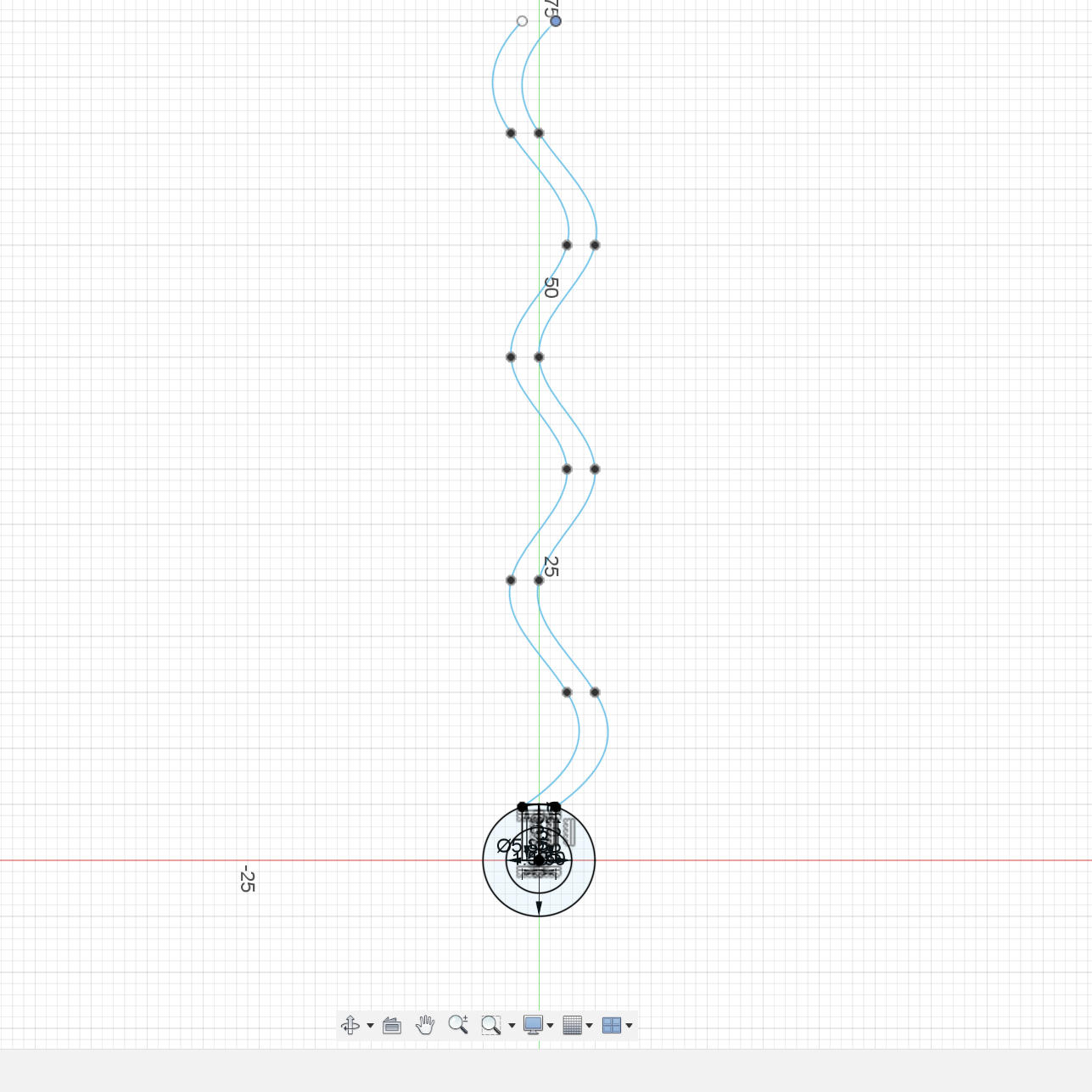

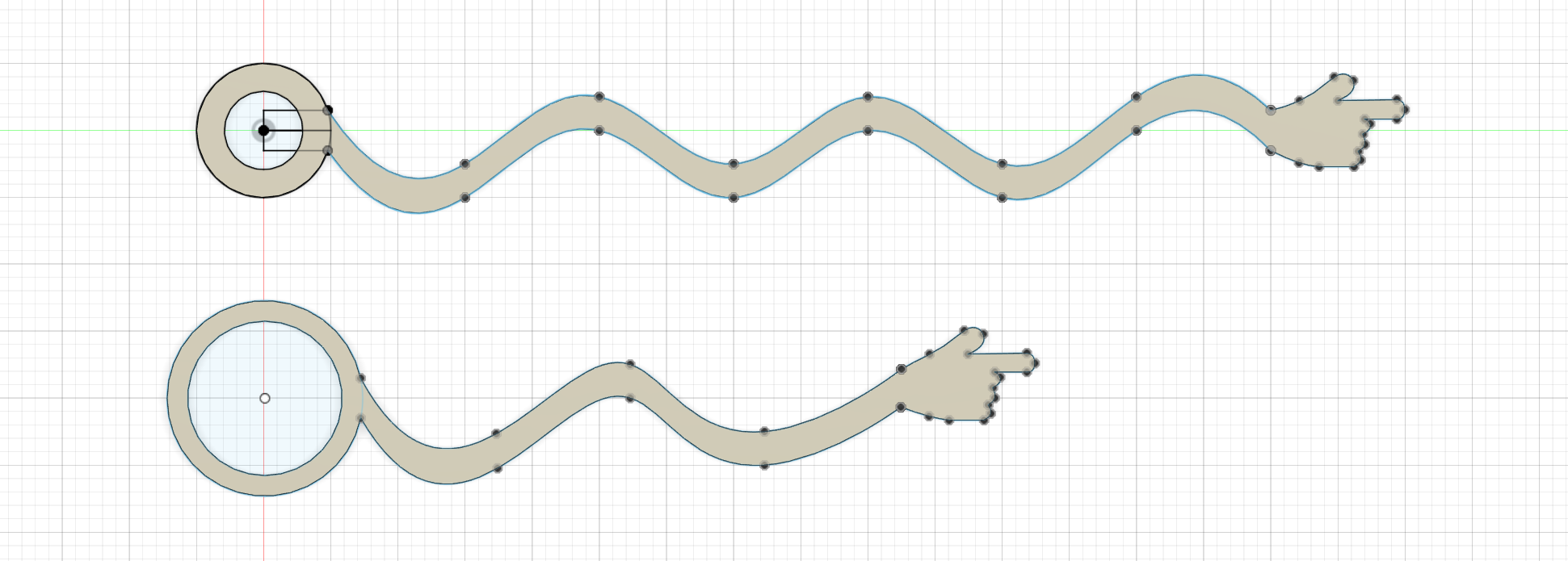

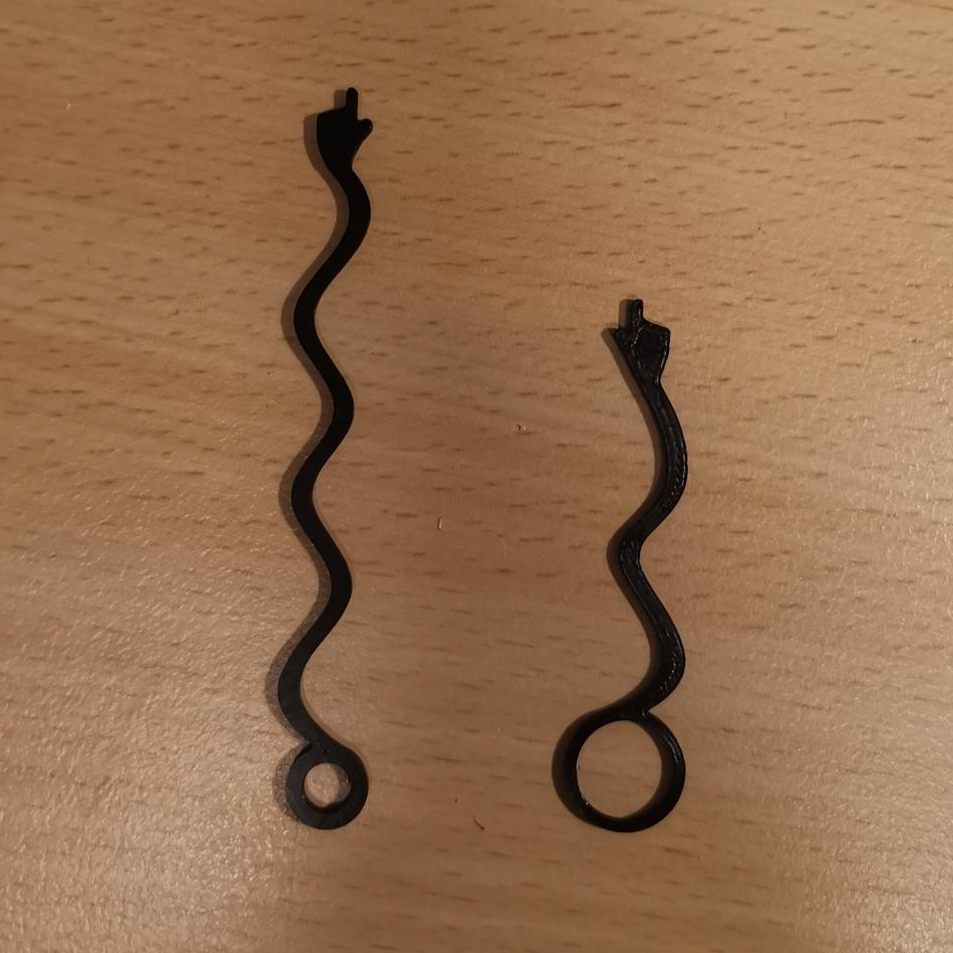

Pendulum Design

- Initial picture

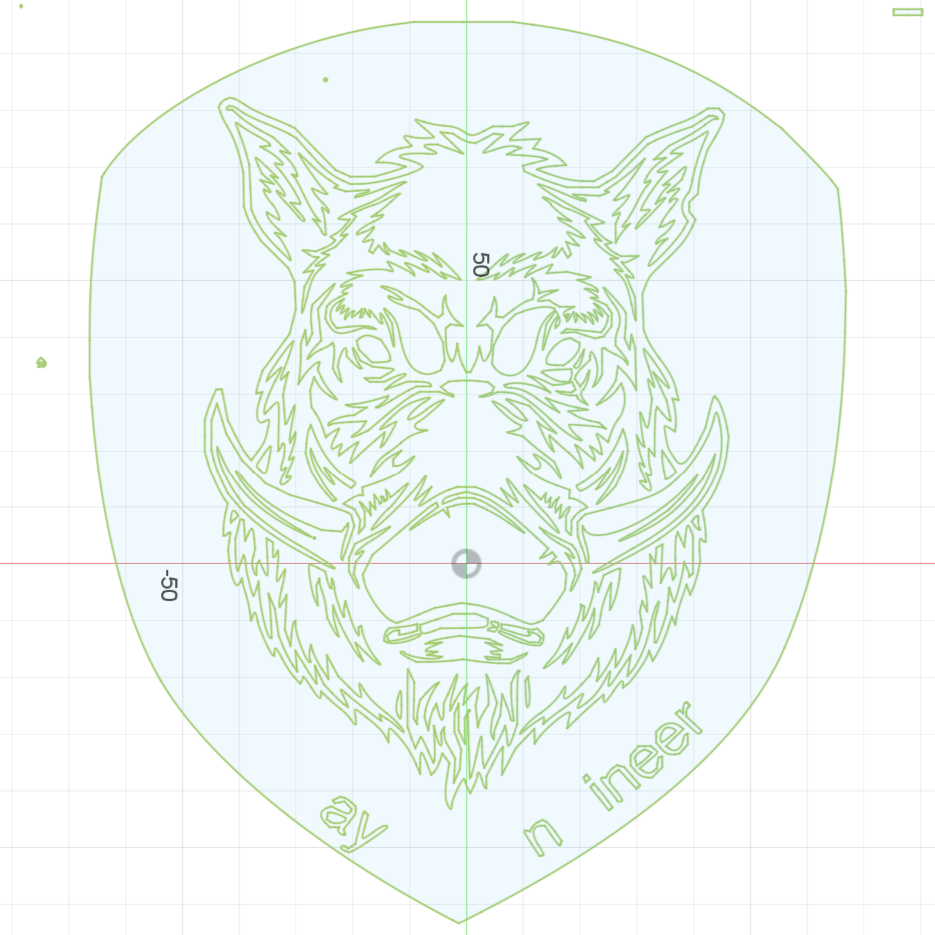

- Incscape

- Create Bitmap of picture

- export .svg

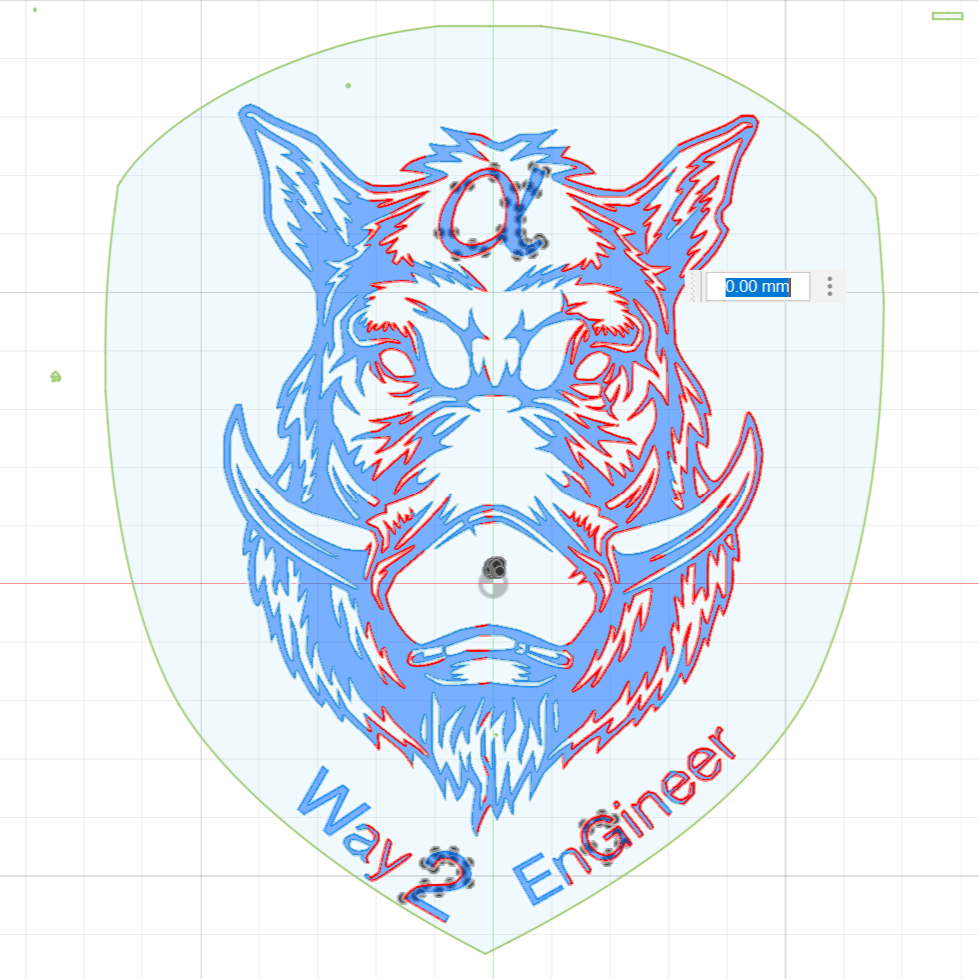

- Import to Fusion 360

- Automatically generates sketch

- delet extra generated sketches

- Add missing sketches due to bad contrast of original picture (alpha and some letters)

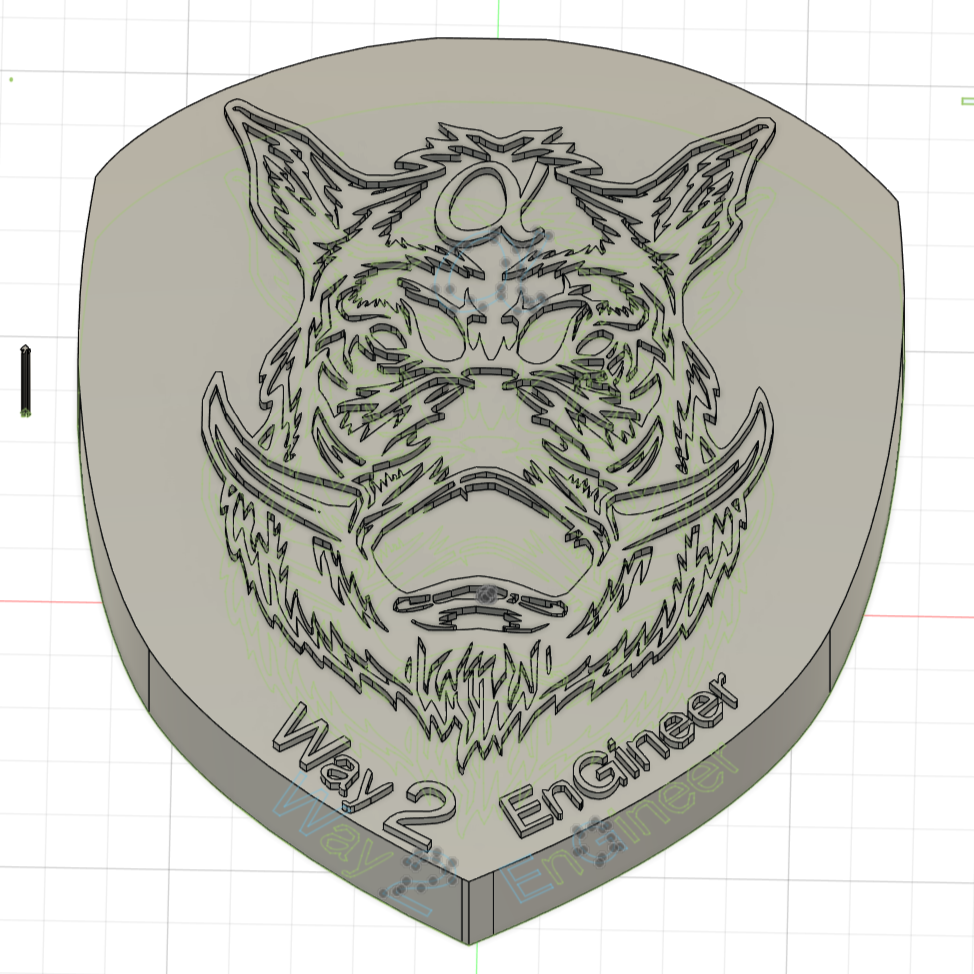

- Extrude base 20mm

- Extrude sketch 22mm

- Create ⌀7mm circle sketch at bottom of body

- Use extrusion to cut and creat place for rod

- Not possible to remove supports if printed in one

- Use offset plane to cut in the middle

- Use offset plane to create pins to connect the two parts

- Use pins to create cutout

- Printed using Prusa MK 4

- deburr

- Printed using Prusa MK 4

- deburr

- Clip together

- Pass fit snapped in tightly

- Fix to pendulum using M6 nut

Final Result

Costs

| Name | Description | Price |

|---|---|---|

| Filament PLA | About 900g | 11.00€ |

| M6 Threaded rod | 1m | 1.99€ |

| M6 Threaded rod | 0.3m | 1.99€ |

| M6 nuts | Pack of 30 | 1.99€ |

| Rod coupler | 2x | 2.99€ |

| Lubricant | Silicon based | 4.49€ |

| 24.55€ | ||