CNC milling

Instruction Manual CNC – Fräsmaschine ICV 4030

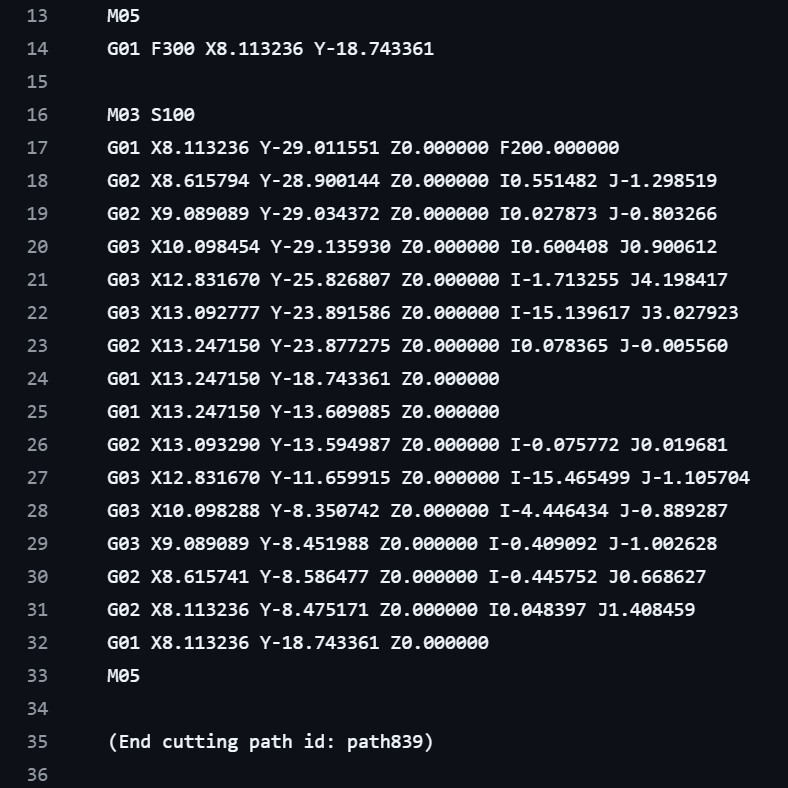

CNC milling is a precise and versatile manufacturing process, especially suited for working with wood and plastics, but also metals The process begins with designing the part in CAD software, which is then converted into a set of machine instructions using CAM (Computer-Aided Manufacturing) software. This CAM program generates the G-code, which tells the CNC machine exactly how to move the cutting tool, at what speed, and along which path to achieve the desired shape. The G-code is highly adjustable, allowing for changes in toolpaths, cutting speeds, and depths to suit specific project requirements or material properties.

Before starting the milling process, the machine’s coordinate system must be set by defining the zero point for each axis. This is typically done by carefully positioning the cutting tool and slowly scratching or touching the surface of the workpiece to establish the starting point for X, Y, and Z axes. This step is crucial for accuracy, as even small errors in zero setting can lead to misaligned cuts or tool collisions. Modern CNC machines often use digital touch plates or edge finders to make this process more reliable and repeatable.

One of the main advantages of CNC milling for wood and plastics is the ability to produce complex shapes with high precision and repeatability. The process is highly automated, reducing the need for manual intervention and minimizing human error. However, there are some drawbacks: the initial setup can be time-consuming, and the machine requires regular calibration and maintenance to ensure optimal performance. Additionally, not all plastics and woods react the same way to milling, so some trial and error may be needed to find the best cutting parameters for each material.

What makes CNC milling particularly interesting is the flexibility it offers. The G-code can be easily modified to accommodate design changes or different materials, making it ideal for prototyping and small batch production. The ability to precisely control every aspect of the milling process—from tool selection to feed rates—allows for creative experimentation and optimization, which is especially valuable in production engineering and advanced manufacturing projects.